Container Cubing Optimization for Sustainable and Profitable Logistics in Latin America

In a context where sustainability is no longer optional, but a growing requirement in global markets, Latin American companies face a double challenge: staying competitive while reducing the environmental impact of their logistics operations. The good news is that sustainability and profitability are not necessarily conflicting goals. A clear example of this synergy is optimized container cubing, a key practice that helps reduce both costs and emissions at the same time.

Logistics Sustainability in Latin America: An Opportunity to Innovate and Reduce Environmental Impact

Latin America, with its abundant natural resources and key role in international trade, has a particular responsibility in the transition toward greener logistics. Optimizing the use of container space not only improves operational efficiency but also helps reduce the carbon footprint of transportation, one of the sectors with the greatest environmental impact.

Load Optimization and Cubing: Keys to Sustainable Logistics in LATAM

Container load cubing optimization is much more than just making the most of available space. It involves strategic planning of cargo distribution to maximize usable capacity, lower costs, and reduce environmental harm.

Fewer Containers Thanks to Optimized Cubing

An optimized loading plan allows more goods to be consolidated per container, reducing the total number of units needed for the same operation. This results in a more efficient supply chain, with lower resource consumption and reduced transportation and storage costs.

Efficient Planning That Reduces Packaging and Waste

Accurate cubing planning ensures that loads are properly distributed and stabilized within the container. This reduces the need for extra protective materials and prevents damage caused by movement during transit, helping to minimize waste and logistical residues.

Space Optimization in Warehouses and Logistics Centers

Good load planning and container cubing have a direct impact on warehouse and logistics center management. This not only maximizes the use of available physical space but also improves operational productivity, speeds up receiving and dispatch processes, reduces storage-related costs, and contributes to a more agile and controlled supply chain.

Efficiency in the Use of Containers as a Logistics Unit

Optimized cubing allows strategic consolidation of cargo within each container, reducing the total number of units needed for a single logistics operation. This improves container usage efficiency, minimizes unnecessary movements, and prevents the shipping of underutilized units. As a result, intermodal transport capacity is optimized, freight costs are reduced, and the environmental footprint caused by redundant logistics operations is minimized.

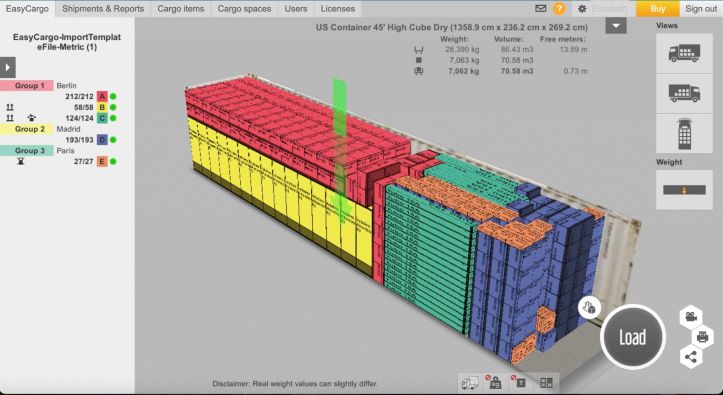

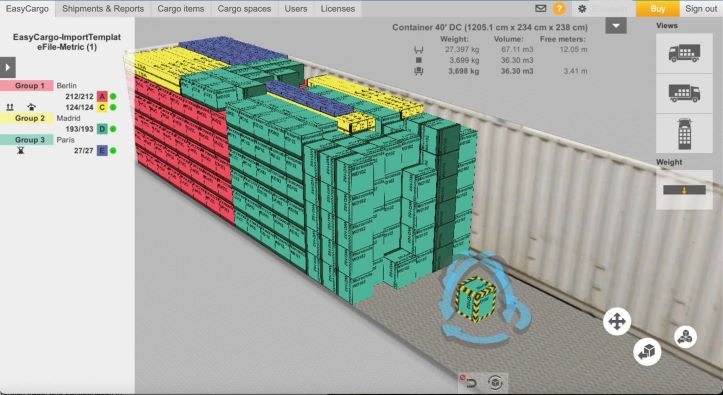

EasyCargo: Load Planning and Cubing Optimization Software for Containers

To achieve these results, many companies are adopting digital tools like EasyCargo, a software designed to plan, organize, and optimize loading in containers, trucks, and other logistics spaces.

This tool enables efficient cargo distribution, directly helping to reduce unnecessary trips, improve logistics planning, and make the entire supply chain more sustainable. If you want to learn more about how to create your first load using this logistics software, check out the following article: «Learn the Basics of Load Planning.»

Its main features include:

- Real-time 3D load visualization with rotating view, zoom, and intuitive interface.

- An optimization algorithm that considers dimensions, weight, constraints, priority groups, and axle load.

- Automatic cubing calculation, which is especially useful to speed up load planning.

- Bulk import of items from Excel and the option to integrate with ERP systems like SAP via API.

- Step-by-step reports, printable and shareable via link, improving both internal (team) and external (customer) communication.

Although it does not directly calculate CO₂ emissions, EasyCargo allows precise visualization of space utilization, which serves as a basis for estimating the impact of each shipment.

Benefits of Optimizing and Planning Container Load Cubing for Companies in Latin America

- Cost savings in logistics by reducing trips and making better use of space

- Improved load planning, reducing errors and delays in the process

- Lower environmental pollution by decreasing transport emissions

- Competitive advantage for companies that adopt planning and cubing technologies

Latin American Companies Optimizing Load Cubing to Become More Competitive and Sustainable

Companies in sectors such as food, manufacturing, foreign trade, and transportation in countries like Colombia, Mexico, Argentina, and Chile are already applying optimized cubing and container load planning practices with EasyCargo. The benefits include:

- Fewer trips are required for the same operation

- Less time spent preparing load proposals

- Better load distribution visualization, thanks to easy-to-understand 3D reports

- Operational savings that can be reinvested in sustainable measures

A recent example is Savino del Bene (a logistics and transportation leader in Argentina), which successfully automated its load proposals and improved the accuracy of its logistics planning with EasyCargo.

Planning and Optimizing Container Loads Also Means Planning a Sustainable Future

Optimized container cubing is no longer just a technical matter. Today, it represents a key tool for building sustainable and resilient supply chains. In Latin America, its implementation can make the difference between costly, polluting logistics and modern, efficient, and environmentally conscious logistics.

Adopting technological solutions like EasyCargo is a strong step toward a future where every cubic meter counts, not only in terms of space but also in environmental impact. Take action today and start using this load optimization software with a free 10-day trial.